1. Aluminum shell packaging, good heat dissipation performance, suitable for installation of heat dissipation panels, can be used in harsh environments for a long time

2. Small size, high power load.

3. High insulation, using flame-retardant inorganic materials for integrated packaging, with good seismic resistance.

4. Multiple wiring methods, easy to install.

5. Widely used in the power supply, frequency converters, elevators, stage audio, and high-end equipment industries.

6. Accuracy range: ± 1%, ± 2%, ± 5%, ± 10%

It is composed of three parts: a resistance wire with a certain electrical resistivity, a skeleton, and an outer shell. Among them, the resistance wire is the main part of the aluminum shell resistor, responsible for limiting the current; The skeleton is used to support the resistance wire and maintain a certain distance from the shell; The outer shell serves to protect the internal resistance wire and framework.

Features:

High temperature resistance: Due to the use of aluminum alloy material as the outer shell of the aluminum shell resistor, it has a high melting point and good thermal conductivity, allowing the aluminum shell resistor to work normally in high temperature environments.

Moisture resistance: The shell of the aluminum shell resistor has good sealing performance, which can effectively prevent moisture and impurities in the air from entering, thereby ensuring its stability in humid environments.

Vibration resistance: The aluminum shell resistor has a compact structure, and the connection between the shell and the skeleton is firm, which can withstand a certain degree of vibration and impact.

Corrosion resistance: The outer shell of the aluminum shell resistor is made of aluminum alloy material, which has strong corrosion resistance and can work in harsh chemical environments for a long time.

Advantages:

High stability: Aluminum shell resistors have good stability performance and can maintain their resistance value for a long time, meeting the stability requirements of various electronic devices for resistors.

Long lifespan: Due to its excellent resistance to high temperature, humidity, vibration, and corrosion, aluminum shell resistors have a longer service life and lower equipment maintenance costs.

High reliability: The aluminum shell resistor has a simple structure, convenient installation, and can work stably in various harsh environments, improving the reliability of electronic equipment.

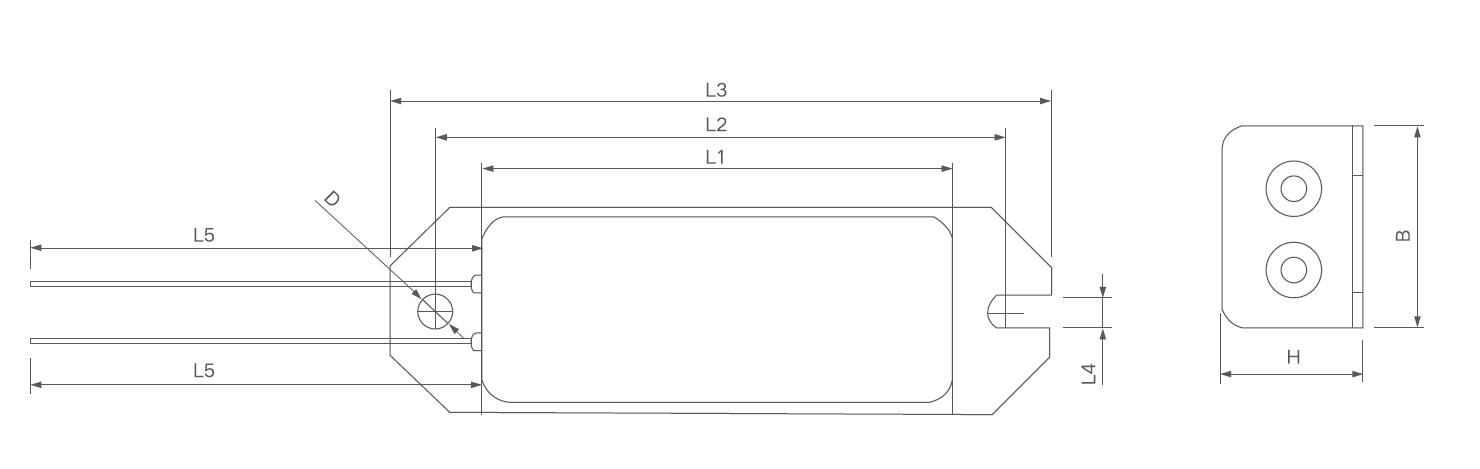

| Model TYPE | Dimensions (mm) |

Resistance range Resistance range |

Maximum insulation voltage Maximum insulation voltage |

||||||

| L1 ± 1.5 | L2 ± 1.5 | L3 ± 1.5 | L4 ± 0.5 | B ± 1.0 | H ± 1.0 | D ± 0.5 | |||

| RXC60W | 75 | 90 | 100 | 5.5 | 30 | 13 | 5.5 | 0.1R-2.7K | 600V |

| RXC80W | 100 | 115 | 130 | 5.5 | 42 | 19 | 5.5 | 750V | |

| RXC100W | 100 | 115 | 130 | 5.5 | 42 | 19 | 5.5 | 900V | |

| RXC120W | 122 | 140 | 130 | 5.5 | 42 | 19 | 5.5 | 1000V | |

| Inspection items | test method | performance requirement |

| temperature coefficient | Measure the resistance value at room temperature and 100 ℃, and calculate the change in resistance value for each degree | ± 250ppm/℃ |

| Short term overload | 5 times rated power for 5 seconds | △ R ≤ ± (2.0% R 0.05 Ω) |

| Insulation voltage | According to the voltage specified in the table | △ R ≤ ± (0.5% R 0.05 Ω) |

| temperature | 250 ℃, 2 hours | △ R ≤ ± (3% R 0.05 Ω) |

| High frequency vibration | Frequency 10-200Hz, peak value 20g, 2 directions, time of 6 hours | △ R ≤ ± (3% R 0.05 Ω) |

Tel

Service

TOP